Minimum thickness of screed for underfloor heating

By Staenis | | Manual

What is the minimum thickness of screed on underfloor heating?

Planning to install a floor structure with underfloor heating? Then you also need to provide an insulation layer and a suitable screed. After all, underfloor heating is installed in or on an insulation layer. What type of screed can you use with underfloor heating and how thick should your screed be? Discover the recommended screed thickness for your project and get useful tips.

Why provide a screed?

When installing a floor, you should always provide a screed or screed floor. This provides a flat surface on which you can lay floor coverings such as tiles, multi-layer parquet, natural stone, PVC floors, etc. You can also place electrical conduits, heating, ventilation and drainage channels in it to obtain a perfectly even surface, although it is of course better to place these utilities in the filling layer. If you opt for underfloor heating, your screed will be placed in or on an insulation layer, instead of directly on your supporting floor. This is called a floating screed, because there is no direct contact between the screed and the supporting floor, walls, skirting boards, sills, etc. Want to save on the costs of your project? Discover a handy solution that allows you to install your own floating screed floor as a novice handyman.

Floating screed, a suitable subfloor for underfloor heating

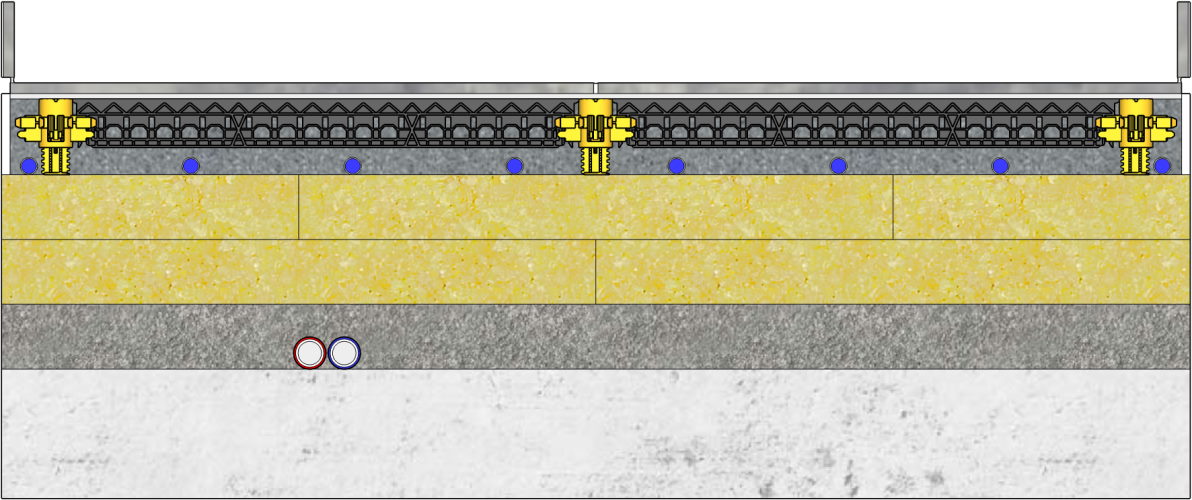

Underfloor heating is therefore installed either in or on top of an insulation layer. This insulation layer is placed between the load-bearing floor and the screed. Thanks to the insulation, the heat from your underfloor heating cannot escape downwards. What type of screed is placed on this insulation layer? In practice, underfloor heating is combined with a floating screed. Such a floor screed must always have a minimum thickness of 5 cm on insulation or above underfloor heating pipes. The recommended thickness of the screed depends on the type of screed, the composition of the mortar, and the type of underfloor heating system. We discuss the required screed thickness per type of underfloor heating (wet or semi-dry system). Haven't hired a screeder yet? With this innovative DIY system, you can easily install your floating screed yourself.

Which type of screed to choose for a floating floor?

If you want to install a floating screed floor, you have the choice between a traditional cement-based screed and an anhydrite liquid screed. Cement-based screed consists of a mixture of sand and cement and is prepared with water. There are different types: bonded and unbonded, floating and sloped screed. On floor insulation that has a thermal and/or acoustic function, which is the case with underfloor heating, you install a floating screed. Anhydrite liquid screed is often used in larger construction projects or when there is limited floor build-up height in renovation projects, because it can be applied thinly. Discover here the most suitable floor build-up for your project.

Underfloor heating: will you choose a wet system or a semi-dry system?

Underfloor heating systems with screed can be roughly divided into two types of systems: wet systems and semi-dry systems. With wet systems, the heating pipe is laid on the floor insulation and therefore at the bottom of the cement screed. It is the obvious choice for new-build homes. With a semi-dry system, on the other hand, the pipes of the underfloor heating are placed at the top of the insulation layer. Thanks to the low installation height, the semi-dry system is ideal for renovation projects, apartments and timber frame construction. Underfloor heating with a semi-dry system costs a little more than the wet system, but there are interesting advantages. Easier installation due to the pre-formed insulation boards, better upward heat emission and a fast homogeneous heat distribution, for example.

Average thickness of screed in a semi-dry system

How thick should your screed be if you choose underfloor heating with a semi-dry system? With underfloor heating using a semi-dry system, the heating pipes are placed in the insulation layer. The insulation consists of preformed insulation boards made of styrofoam or polystyrene. On top of the insulation layer with integrated underfloor heating comes a thin finishing screed. If you opt for traditional, cement-bound screed, your floor screed should be 6 cm thick. If you use anhydrite liquid screed, the screed should be 4 cm thick.

Average screed thickness for a wet system

What is the recommended screed thickness when opting for underfloor heating with a wet system? With underfloor heating using a wet system, the heating pipes are placed on the insulation layer. In this case, the screed is a finishing layer in which the pipes are embedded. The heating pipes are therefore located within the screed itself. It is called a wet system because the screed is poured wet over the pipes, and the pipes are completely surrounded by screed. To achieve good heat distribution, you must provide at least 4.5 cm of additional screed space above the underfloor heating pipes. This brings the total thickness of the screed to 7.5 to 8 cm.

How thick is a floor structure with underfloor heating?

If you install underfloor heating, your floor structure will therefore be thicker than normal. Exactly how much thicker depends on the type of system. If you opt for underfloor heating with a semi-dry system, the thickness without extra insulation varies between 8.5 and 14 cm. A semi-dry system is therefore ideal for locations with limited build-up height (e.g. apartments, renovations, etc.). With the wet system, the build-up height is thicker and you need at least 12 cm in height, of which 4.5 cm is for sprayed PUR or insulation screed. The wet system is therefore interesting when there is sufficient build-up height, for example in new construction.

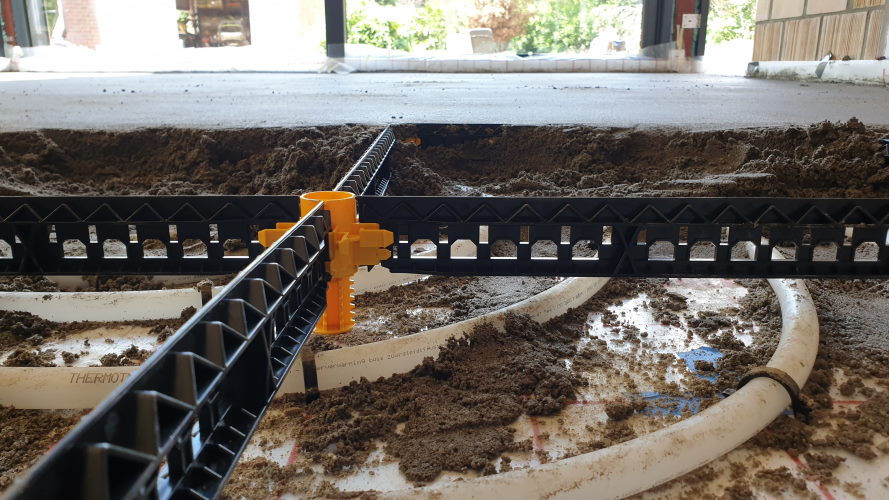

Do-it-yourselfer? Lay your own screed

Don’t feel like waiting a long time for your screeder? Why not install your floor build-up yourself? You can do it easily and quickly with the StaenisGrid screed grid. This allows you, as a DIYer, to achieve a professional result without much effort. How does the screed grid work? You place a row of plastic grids, set them to the correct height, fill them with screed, and level the screed to the top of the grid. The grid stays perfectly in place the whole time and ensures a flat and crack-free screed floor. Because the grid is divided into sections of 0.25 m², the internal stresses are greatly reduced, allowing you to eliminate the cost of a decoupling mat. This saves you money and time. And yes, the system is perfectly compatible with wet and semi-dry underfloor heating. Curious? Watch the introduction video and discover here how to install your floor build-up yourself.

Are you going to install your floor structure yourself using the StaenisGrid? Then, for a traditional sand-cement screed with underfloor heating, it is best to use a screed thickness of at least 7.5 to 8 cm. You can easily order your StaenisGrid, the necessary fillers, and the installation tools online via the webshop. Want to see the system with your own eyes before you decide? Visit a Sack self-build showroom.

Buy underfloor heating pipes from Henco