Types of floor constructions

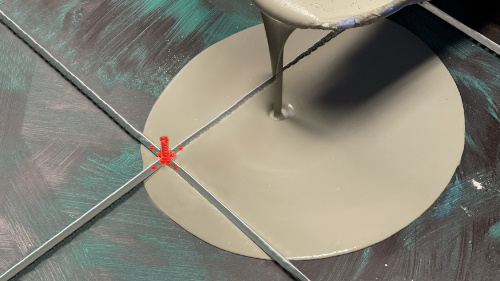

The floor structure is an important part of construction or renovation projects and there are various types available, such as screed, insulation screed, dry fillers, drainage mortar, and self-leveling compound. Each type of floor structure is specifically suitable for a certain space and offers different advantages, such as high load-bearing capacity, insulating properties, low height, or a sustainable solution.

When choosing the right floor build-up, it is important to consider whether the structure of the house is suitable, whether underfloor heating will be installed, and whether the floor will be placed on an upper level. Staenis offers floor build-up solutions that are easy to install, stress-free, and have unique advantages, such as a lighter design or an environmentally friendly dry floor.

- Choose a filler below: screed, (tileable) insulation screed, dry fillers, self-leveling compound or drainage mortar based on the room.

- And receive only information about your specific floor structure.

Do you have construction or renovation plans and want to get started yourself installing your floor structure? Fantastic, we love that hands-on mentality!

Do you want to renovate the bathroom, or perhaps redesign the attic space now that the children are a bit older? Or maybe it's time for a new terrace?

Does the new floor need to be insulated or acoustically perfect? Is the structure of the house strong enough for a new floor construction? Will underfloor heating be installed? Will the floor be installed on an upper floor? And which floor finish will you choose?

You can already tell: every floor structure has different properties, and everyone has different requirements for their future floor. That’s why we are happy to help you!

Display models

at Sack Self-Build

With Staenis, we focus on online visibility, but through the collaboration with Sack Zelfbouw, we can also showcase the grid system offline through open visits to the showrooms of Sack Zelfbouw.

Discover 4 different floor constructions in real life at Sack Zelfbouw

Sack Self-build