Lay a perfectly flat floor yourself

Get a professional result without experience or hassle

- A flawless floor, even without professional knowledge

- 50% faster – start when you're ready

- Work at your own pace – never wait for anyone

- Seamless system – no cracks, no expansion joints

Why choose Staenis?

Traditional screed vs. 4 Staenis solutions

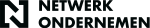

Traditional Screed

- Waiting for an expensive installer

- Risk of cracks and tears

- Expansion joints required

- 28 days drying time or longer

- High chance of warping

- Long-term start-up protocol for underfloor heating

- Uneven after drying possible

Staenis leveling floor

- Leveling from 1 mm to 5 cm

- Extra reinforcement thanks to grid

- Top layer quickly and precisely to level

- Ideal for renovation/uneven surfaces

- Light crack-bridging for extra security

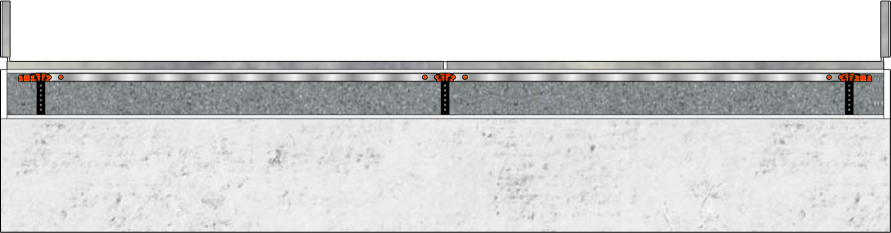

Staenis screed floor

- Install yourself, no installer required

- Guaranteed crack-free

- No expansion joints up to 200 m²

- Quickly ready and flat

- Light and quick-drying

Our systems & heights

- Compound leveling grid — 1 mm to 5 cm

- Screed grid — ± 5 to 13 cm

- Dry floor grid — ± 5-13 cm + plating

- CircoFloor — ± 9–22 cm + plating

Staenis dry floor

- Dry, light build — no waiting time

- Can be directly laid with OSB/Durelis

- Perfect results, even without experience

- Dismountable and reusable

- Attic/conversion ideal

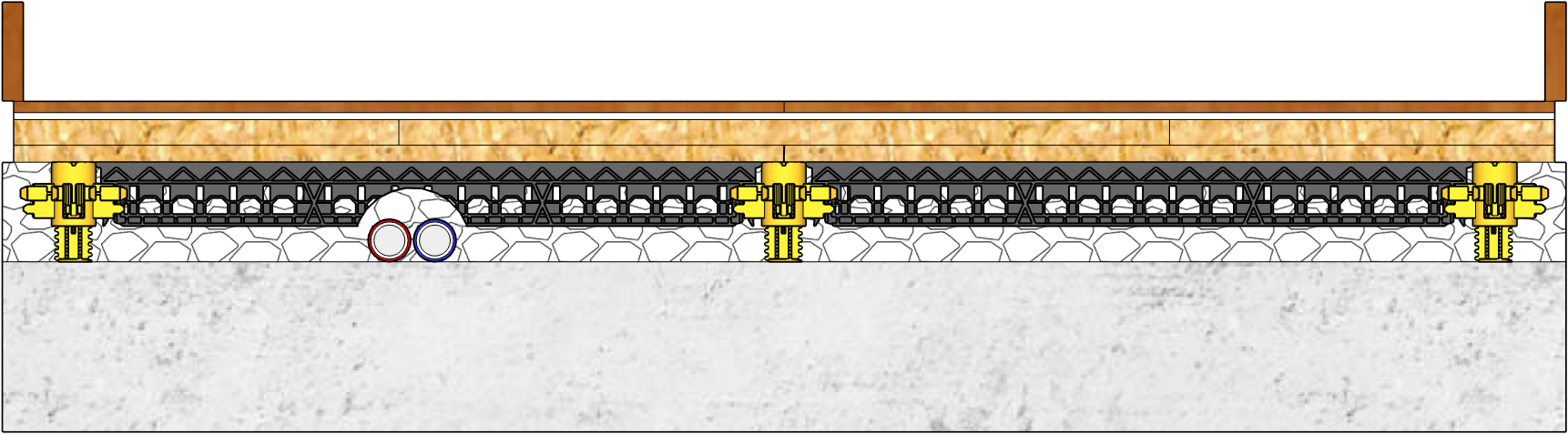

Staenis CircoFloor

- Circular, demountable and modular

- Load capacity up to 2.8 tons/m² (adjustment screws)

- Green alternative to PUR+screed

- Low environmental impact

- High insulation value and acoustic damping

Do you have any questions?

Tip: Add or edit your question as you receive additional information.

(Approximately 100 seconds of thinking time per question) -> Start a new conversation here <-

(Approximately 100 seconds of thinking time per question) -> Start a new conversation here <-

Staenis in numbers

4.000+

customers

97%

customer satisfaction

> 150.000 m²

placed