Laying your own dry floor

By using dry products in combination with the StaenisGrid, you can easily and directly cover your floor with OSB (or Durelis) and finish it with a floor covering such as laminate, multilayer parquet, etc. You also ensure that your floor structure becomes reusable/circular/environmentally friendly, thus contributing your part to the climate.

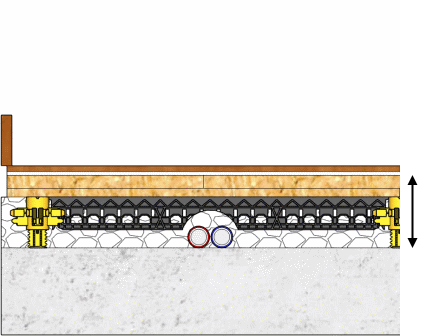

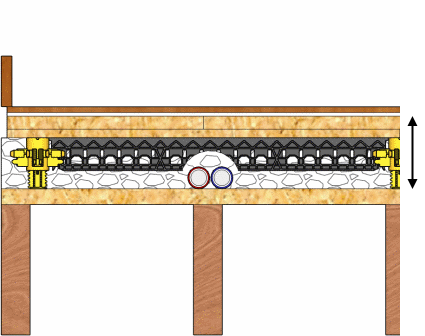

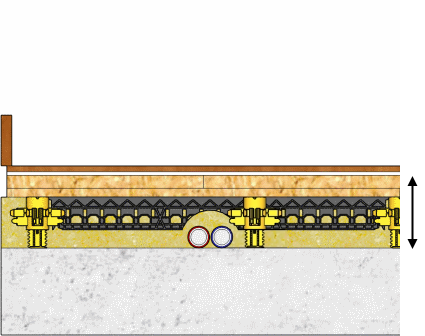

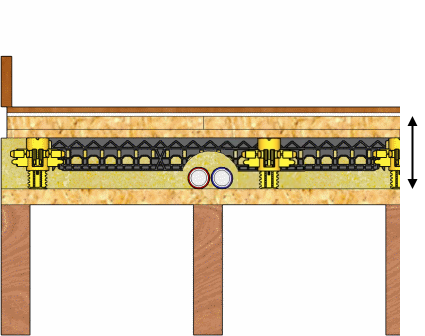

The Staenis grid serves as a wooden slatted frame that's easy to adjust in height and is ideal for attics. The grid can be filled with load-bearing fillers such as recycled aerated concrete granules or insulating fillers such as rock wool insulation, EPS beads, cork granules, and lime hemp, or without filler.

By combining the Staenis grid with recycled aerated concrete granules and OSB, you save on expensive gypsum fibre boards (+25 euros/m²) and expensive levelling granules.

You can screw the OSB or Durelis into the battens of the StaenisGrid. Insulating, soundproof, and fire-resistant floor structure, depending on the filler and boarding used.

30 kg less CO² emissions per m² = 10 x less CO² emissions compared to screed

Up to 15 dB less contact noise by using felt pads under the adjustment screws.

Applications

Circular: By using aerated concrete, the dry floor becomes more load-bearing and sounds acoustically better when you walk on it.

As wooden joisting: In this project, the Staenis dry floor grating is used as a wooden grating. This is now easily achieved thanks to the fiber-reinforced dry floor grating.

Dry floor: A standard dry floor with leveling granules tends to settle over the years, but with the StaenisGrid, the floor always remains nicely at the correct height.

Filling layer: You can also use the StaenisGrid in combination with cellular concrete leveling granules as an environmentally friendly fill layer under insulation boards.